What Determines the Reusability of a Foldable Storage Box?

Defining Reusability in Foldable Storage Boxes

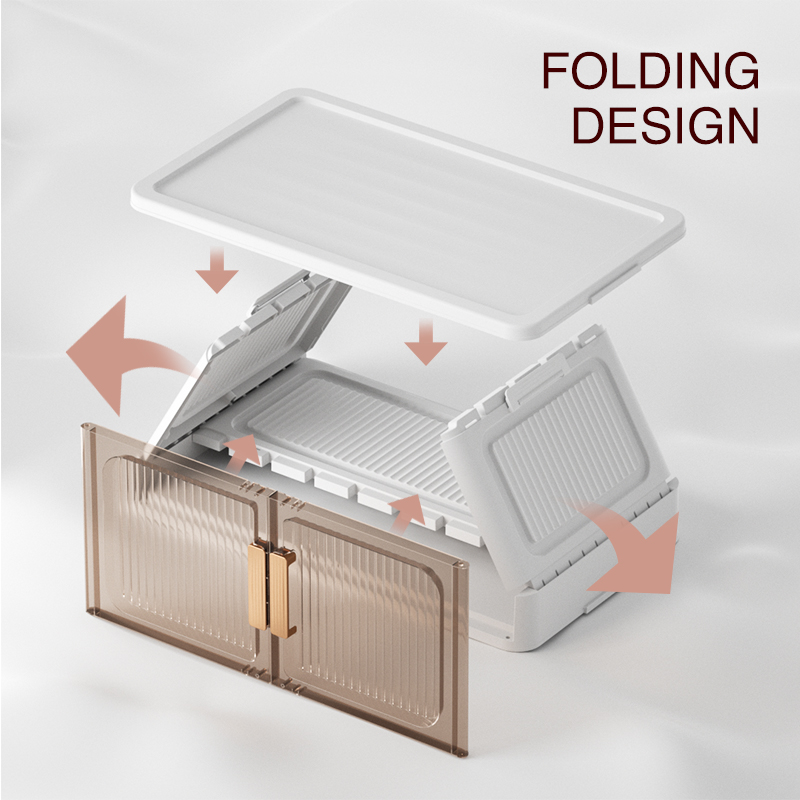

Reusability in foldable storage boxes refers to their ability to withstand repeated folding cycles while maintaining structural integrity and functionality. Unlike single-use packaging, reusable designs prioritize durable joints, tear-resistant materials, and intuitive folding mechanisms that prevent deformation.

Key Factors Influencing Long-Term Reuse Potential

Three primary factors determine reuse potential:

- Material fatigue: Plastic degradation at folding points after repeated stress

- Design efficiency: Hinge geometry and reinforcement at high-stress zones

- Handling practices: Proper alignment during folding/unfolding to avoid misalignment

Improper handling accounts for 63% of premature failures in foldable containers, according to a 2025 logistics optimization study.

How Material Quality Impacts Durability and Reusability

Material selection directly correlates with folding cycle performance:

| Material | Avg. Folding Cycles | Temperature Tolerance | Impact Resistance |

|---|---|---|---|

| HDPE | 800+ | -30°C to 60°C | High |

| PP | 500-700 | -20°C to 80°C | Moderate |

| ABS | 300-500 | -10°C to 70°C | Low |

When it comes to plastic materials, high density polyethylene or HDPE really stands out because of how flexible its molecules are and how well it spreads out stress across its structure. According to some recent tests published in the Material Performance Study back in 2025, HDPE containers kept about 95 percent of their original strength even after being folded 500 times. That's pretty impressive compared to polypropylene containers which only held onto around 82% of their integrity under similar conditions. Warehouse managers know this matters a lot since these containers can last anywhere between three to five years with regular daily usage if handled correctly. Of course, nobody wants to see containers failing mid-shift so proper care remains essential despite HDPE's inherent toughness.

Durability After Repeated Folding: Stress, Wear, and Lifespan

Structural Integrity Under Repeated Folding Cycles

Repeated folding creates cumulative stress at hinge points, where material fatigue accounts for 73% of foldable storage box failures (Journal of Materials Research 2024). Quality boxes use reinforced polypropylene joints that maintain structural integrity through 250+ folding cycles before showing measurable deformation.

Common Failure Points in Plastic Foldable Storage Boxes

Industry studies reveal three critical vulnerabilities:

- Hinge cracks (58% of failures) from uneven pressure distribution

- Edge warping (27%) caused by temperature fluctuations during storage

- Locking mechanism wear (15%) from friction during repeated assembly

Lab and Field Data: Performance After 500+ Folds

Accelerated testing shows high-grade foldable storage boxes retain 89% of original load capacity after 500 folds when:

- Fold angles stay within engineered limits (±15° tolerance)

- Weight distribution follows manufacturer guidelines

Field data from durability testing protocols confirms boxes used in daily warehouse operations average 7.2 years of service before replacement.

Case Study: Reusable Foldable Boxes in Warehouse Logistics

A Midwest retailer achieved 93% reuse efficiency across 18-month pallet cycles by:

- Implementing fold-tracking sensors to prevent overuse

- Establishing quarterly hinge lubrication schedules

- Training staff on proper unfolding techniques

This protocol extended box lifespan by 42% compared to industry averages, demonstrating how systematic handling maximizes reusability.

Folding Mechanisms and Handling Practices That Extend Box Life

Engineering Design of Folding Joints and Hinges

The lifespan of foldable storage boxes hinges on engineered stress points. Leading manufacturers use glass-fiber reinforced nylon hinges that withstand 10,000+ folds according to 2023 material fatigue testing. Cruciform base designs distribute weight evenly, reducing crease fatigue by 37% compared to standard folding joints.

Best Practices for Folding and Unfolding Foldable Storage Boxes

- Align side panels vertically before initiating the fold sequence

- Engage all locking tabs during assembly to prevent uneven stress distribution

- Avoid temperature extremes below 5°C where plastics become brittle (ABS maintains flexibility best at -20°C)

A 2024 logistics study showed facilities using trained folding protocols achieved 82% higher reuse rates versus untrained teams.

How Improper Handling Accelerates Wear and Damage

Forced folding against natural crease lines creates microfractures reducing load capacity by 15–20% per incident. Warehouse audits reveal 63% of premature box retirements stem from:

- Overstacking beyond rated capacities

- Drag-pulling loaded boxes across floors

- Chemical exposure from improper cleaning agents

Boxes with polypropylene copolymer construction show 40% better resistance to handling abrasion than standard HDPE models based on ASTM D4060 wear testing.

Material Selection and Environmental Impact on Longevity

Comparing PP, HDPE, and ABS Plastics in Foldable Storage Box Construction

The main plastics used in making foldable storage boxes are polypropylene (PP), high density polyethylene (HDPE), and acrylonitrile butadiene styrene (ABS). Each has its own strengths that make them suitable for different applications. Polypropylene is really flexible, stretching anywhere from 150 to 200 percent before breaking, which makes it great for certain uses. However, it doesn't hold up as well when exposed to sunlight over time compared to HDPE. HDPE can withstand impacts better too, around 7 to 10 kJ per square meter versus only 3 to 5 for PP. Then there's ABS plastic that brings together both stiffness and ability to handle temperature changes, so it works particularly well when boxes need to be reused many times in industrial settings. According to a recent report on packaging materials from 2023, HDPE containers generally stay functional after about 300 folding cycles while ABS ones last beyond 500 cycles under laboratory conditions.

| Material | Tensile Strength | UV Resistance | Folding Cycles (Avg.) |

|---|---|---|---|

| PP | 25–35 MPa | Moderate | 150–200 |

| HDPE | 20–30 MPa | High | 250–350 |

| ABS | 60–80 MPa | Low | 400–600 |

Effects of UV Exposure, Temperature, and Humidity on Plastic Durability

Foldable storage boxes don't last as long when exposed to environmental stressors, with lifespans dropping anywhere from 30 to 70 percent based on what they're made of. According to research published in the Polymer Degradation Study back in 2022, polypropylene starts losing half its flexibility after just 1,000 hours under UV light, whereas high density polyethylene keeps about 80% of its original strength. When temperatures fluctuate more than 40 degrees Celsius, ABS plastic joints expand at different rates, which speeds up the wear on hinges over time. And then there's humidity to consider too. At around 80% relative humidity levels, mold and bacteria tend to grow on HDPE surfaces, causing them to wear down about 18% faster than boxes kept in controlled environments. These factors really matter for anyone storing important items outdoors or in basements where conditions aren't stable.

Optimal Storage Conditions to Maximize Reuse Cycles

Preserving foldable storage box functionality requires:

- Temperature stability (15–25°C ideal)

- Humidity control (<60% RH)

- UV-filtered lighting or dark storage

A 10-year analysis of warehouse storage practices found boxes stored at 22±3°C and 50% RH averaged 420 reuse cycles versus 190 cycles in unconditioned spaces. Rotating boxes every 6 months prevents permanent creasing in high-stress zones.

Real-World Reusability Trends in Logistics and Retail

Adoption of Reusable Foldable Storage Boxes in E-Commerce Fulfillment

Since 2020, e-commerce warehouses have really pushed the use of those reusable foldable storage boxes up by around 72%, mostly because companies want cheaper ways to handle returns and get products back into circulation. Big players in this space are starting to roll out artificial intelligence systems that track when these boxes need to be reused, which cuts down on replacement costs by about a third compared to what happened before when people had to manually keep tabs on them. Looking at market trends, the whole reusable packaging business seems set to expand quite a bit. We're talking from roughly nine point four billion dollars in 2025 growing all the way up to twenty one billion by 2034 according to GlobeNewswire's report last year. Foldable designs already take over nearly half of what gets shipped around for things like clothes and gadgets where volume matters most.

Industry Shift Toward Sustainable Packaging (2018–2024 Trend Analysis)

The push for circular economies has really gotten companies to start using reusable packaging again, especially since the EU wants at least 40% of transport packaging reused by 2030. According to the latest Material Efficiency Report from 2024, almost 6 out of 10 retailers are now going with foldable containers instead of those one-time use boxes they used to rely on so much back in 2018 when only about 1 in 5 did this switch. Some businesses have started mixing things up with smart systems that track packages through IoT technology along with standard sized boxes that just work better together. These approaches cut down on waste by around a quarter and save roughly 18 cents on each delivery, which adds up pretty fast when looking across all shipments.

Average Lifespan of Foldable Storage Boxes in Retail and Distribution Networks

Testing shows that HDPE folding boxes can handle over 500 cycles in climate controlled retail settings, which is quite a bit better than ABS boxes that only last around 380 cycles or so. When people don't handle them properly though, their life gets cut down somewhere between 30 to 40 percent. Most big distributors (about 8 out of 10) run training sessions for staff, and this has helped extend box lifetimes to anywhere from 3 to 5 full years in practice. These containers really shine in cold chain environments too. After being used every day for 18 months straight, they still hold up pretty well, maintaining nearly 94% of what they could originally carry before any wear and tear set in.

FAQ

What factors influence the reusability of foldable storage boxes?

The reusability of foldable storage boxes is influenced by material fatigue, design efficiency, and handling practices. Proper alignment and careful handling greatly affect their longevity.

How does material quality impact the durability of foldable boxes?

Material quality is crucial, as different plastics offer varying levels of flexibility, UV resistance, and strength. For example, HDPE retains strength better under repeated folds than PP or ABS.

Why is handling important for foldable storage boxes?

Improper handling can lead to premature box retirements, as forced folds and overloading weaken the boxes. Trained handling protocols significantly increase their lifespan.

What are the best practices for using foldable storage boxes?

Best practices include aligning panels before folding, engaging locking tabs, and avoiding extreme temperatures. Training staff on these methods can boost reuse rates significantly.

What are optimal storage conditions for foldable boxes?

Optimal conditions include temperature stability (15–25°C), controlled humidity (<60% RH), and UV-filtered lighting. Proper storage extends reuse cycles and maintains structural integrity.

Table of Contents

- What Determines the Reusability of a Foldable Storage Box?

- Durability After Repeated Folding: Stress, Wear, and Lifespan

- Structural Integrity Under Repeated Folding Cycles

- Common Failure Points in Plastic Foldable Storage Boxes

- Lab and Field Data: Performance After 500+ Folds

- Case Study: Reusable Foldable Boxes in Warehouse Logistics

- Folding Mechanisms and Handling Practices That Extend Box Life

- Material Selection and Environmental Impact on Longevity

- Real-World Reusability Trends in Logistics and Retail